Explaining DIO & GPIO in Industrial PCs

What is DIO?

DIO stands for Digital Input/Output. It is an interface component that allows a computer system to send digital signals to IoT ( Internet of Things) devices or sensors and have them operate a desired way. For example, DIO can control crucial status indicators in factory machinery or switches that rapidly count units on production lines. Digital Input detects the different devices that connect to the interface, while Digital Out relays signals out to the connected devices to perform an action.

What is Isolated DIO and why does it benefit Industrial Applications?

DIO is commonly used in electrically noisy environments, like manufacturing or industrial factory floors, where voltage spikes, ground loops, and common mode signals can occur. These events can cause detrimental down time, operation halt, machinery malfunctions, and damaged electronics. The main reason DIO is used for industrial applications is because of its isolation. This isolating technology is known as opto-isolation where individual pins are physically and electrically separated from one another and all incoming signals coming to and from the DIO ports are transmitted using lights in a closed optical channel called photocouplers. Because there is no physical connection, an external 5W DC IN is needed to power DIO. This gives DIO the capability for wide voltage compatibility for any industrial application whether it is to streamline factory automation, provide real-time data analysis/insights, or optimizing production lines.

What is GPIO?

GPIO means General Purpose Digital Input/Output. Like DIO, it is a programmable interface that lets computer systems send command signals to IoT sensors. These IoT sensors connect to the GPIO through the GPIO pins where it requires an input and an output channel. Input allows the computer system to recognize the IoT device, and the output for the computer system to relay commands/signals to the IoT sensor. Because most of these IoT devices use an ON/OFF configuration, it does not need the complex connectivity of a serial or USB port. GPIO can connect multiple devices simultaneously and is programmable to best suit the user’s operations.

Differences between DIO and GPIO

DIO and GPIO have the same interface or platform, however, DIO is isolated using opto-isolation, while GPIO is non-isolated. DIO provides an additional layer of protection from electrical events that can cause machinery failure if a GPIO was used instead. Additionally, GPIO pins are not sustainable on industrial factory floors due to the amount of shock and vibration that can unsocket or disconnect IoT devices from the channel. DIO are locked into place and provide a reliable connection, making it ideal for operator switches/buttons, machinery status signals, and limit switches.

How does industrial computers use DIO?

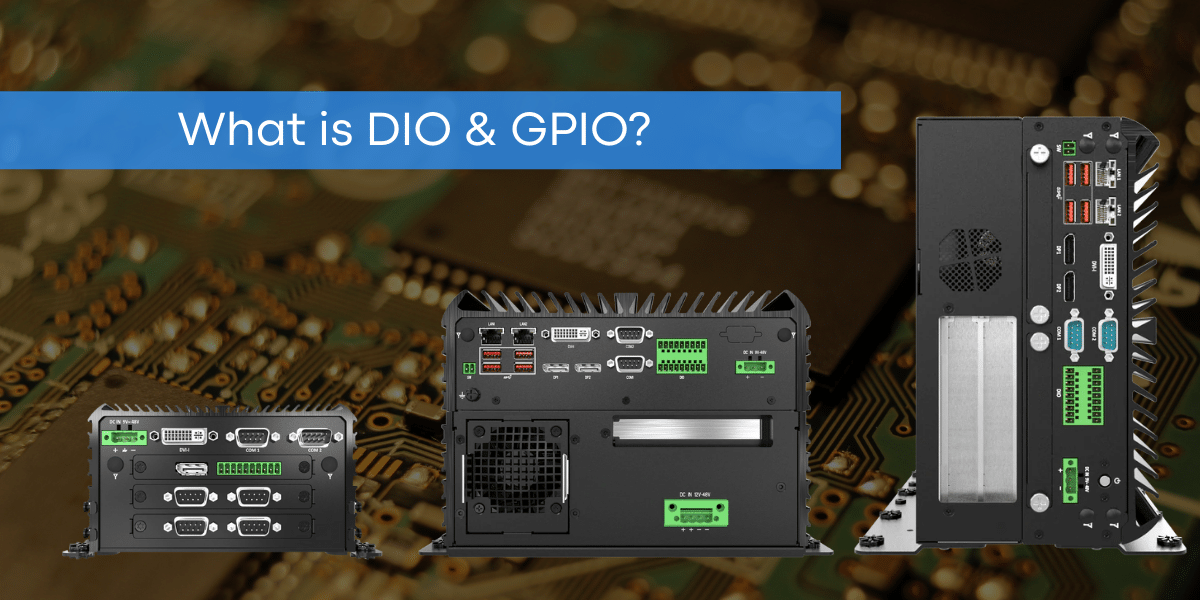

C&T offers 8 and 16 channel isolated DIO connectivity throughout our embedded computer product line along with other I/O compatibilities. The DIO port utilizes a ruggedized feature that uses a phoenix connector that provides industrial-grade locking in a terminal block design. These specific connectors (green in color) are common for industrial automation applications that secure wires together to provide input and output signals. Compared to a traditional PCIe add-in DIO card, C&T’s DIO are built onto the motherboard for additional durability and programmability by using industrial-grade Phoenix connectors. Phoenix connectors, also known as Euroblocks, are solderless connectors that secure connecting wires using screw locking terminals. These connectors can be wired with ease while remaining tightly fastened when connected. A key benefit for combining DIO ports into an industrial computer is the ability for workload consolidation from the computer itself. The industrial computer can directly program specific automation functions and streamline more efficient communication channels from machines and their operators. C&T also provides programmable source code to access and enable specific functions from the DIO port. Overall, C&T industrial computers are being deployed in various environments and applications whether it be remote locations, in-vehicle, on harsh industrial floors, or in automated machinery, DIO connectivity using Phoenix connectors ensures a reliable connection for isolated digital signals.

Check out industrial grade computers with DIO and GPIO ports

How is the DIO Port Different in Industrial Computers?

Although there is no standardized DIO port architecture, they all are functionally the same with minor adjustments in the port layout. Starting with the number of channels that are offered, industrial applications typically use 8 channels (4 input/4 output) to 16 channels (8 input/8 output). DIO ports can look significantly different but at C&T, our 16 channel insulated DIO is on two rows of 8 independent ports with an external 5W DC IN to power the photocouplers, like in our RCO-6000-CML AI Edge Inference Computers. Meanwhile, other architecture can include a single row of 16 channels with an external DC IN or an isolated 5V out with all the pins connected through one connector.

Where to get Industrial PC with DIO?

Our engineers at C&T have designed and manufactured industrial computers for factory automation, AI machine vision, and more for our customers around the globe. C&T's rugged edge industrial PCs are built to maximize your productivity, be reliable and low maintenance, while remaining cost efficient. Contact Us and learn how you can bring your operations to the rugged edge!