Wide Temperature Embedded Systems

The migration of data processing from the highly centralized cloud computing to the edge is pushing the growth of IoT, IIoT, and AIoT devices that proliferate over the past decade. The ability to gather and analyze data locally at the edge has created a myriad of innovative opportunities that require real-time decision-making, low-latency data transfer, and faster overall processing speed. By computing data at the edge, IoT devices are a great option for remote deployments with limited connectivity.

Remote locations are different from offices and factories that have controlled environments. Deploying a system remotely means that the devices must be able to operate under various challenging conditions and extreme environmental obstacles such as extreme temperatures, heavy shocks, constant vibration, and exposures to dust particles and water. From the challenging environmental conditions that we just mentioned, exposure to extreme temperatures is one of the most crucial factors to tackle for edge computing devices to ensure smooth and constant performances amid challenging edge deployments. Therefore, this blog post will discuss the extreme temperature resistance that embedded computers are equipped with.

Where Is All of The Heat coming from?

Understanding the heat source of a computer is beneficial for strategically creating IoT solutions and solve heat problems that may reduce computer performance or damage computer internal components. It is extremely crucial for edge devices to be carefully designed to endure a wide range of extreme temperatures. This is because edge applications can encounter multiple heat challenges in harsh environments, and internal sources while processing heavy workloads.

External Heat Source

Pretty soon edge computers and IoT devices will be all around the world from cities to remote areas performing tasks and analyzing scattered data from different devices and sensors across a multitude of platforms. The rapid advancements of edge computing technologies have led to the solution being deployed in remote locations with tough environmental conditions. These remote locations often experience extreme temperatures, including extreme heat and extreme cold.

For instance, the environmental temperature within the oil and gas industry can be incredibly hot and cold throughout the year. Onshore oil rigs near the Gulf of Mexico can easily reach from 40℃ to 50℃ during a hot and humid summer. Employees working around the oil rig are required to wear special protective clothes to prevent deadly heat strokes. So, this environment can be too hot for standard desktop PCs to handle, especially heat can increase even more if the computer is mounted onto a machine that dissipates waste heat. Oil rigs can also be located in an extremely cold environment like in the Arctic. As such, when deploying a PC, you should deploy an industrial-grade computer that’s capable of handling exposure to extreme heat. C&T has a variety of solutions that can withstand deployment in temperatures that reach 80 degrees Celsius.

The freezing cold environments in the Arctic can easily reach -30℃ and some of the coldest parts in the Arctic Ocean temperature can constantly reach and maintain a low of -40℃. Commercial desktop PCs can quickly fail when get exposed to these extreme environments, therefore, industrial-grade embedded computers are used within these industries to withstand harsh environments. That said, industrial embedded PCs are implemented by various industries as well including the mining industry, autonomous vehicle, livestock management, offshore shipping, and many more where extreme temperature resistance is required.

Internal Heat Source

Another heat source that affects embedded computers comes from within the computer itself. It is the waste heat that is generated from the internal systems that are consists of various components such as CPU, GPUs, SSDs, RAMs, power supply, and more. Essentially, heat is generated as waste from the processors' effort to manage the behavior of the electrons that flow around within the systems. Workloads and heat waste are positively correlated, the more workloads the system is performing, the more active the chips are, and thus more heat is generated and trapped inside the system.

That said, CPUs and GPUs are the two components that generate the most heat inside of the system. Therefore, most computer systems makers focus on cooling the CPUs and GPUs to dissipate the heat, GPUs even have their own cooling system. Edge computing is implementing AI, machine learning, and deep learning into their solutions which may cause heavier workloads and end up with more heat waste for the whole system. That said, it is important to focus on how to dissipate these components' heat when designing the cooling architecture.

What Else You Should be Aware Of?

Here we will talk about the 3Ts you should be aware of and these are TDP, T-Junction, and Thermal Throttling. TDP stands for thermal design power, it is basically the largest amount of heat that can be produced by the processor when running real applications without passing its device’s thermal limits. TDP is measured in Watts, it shows how much energy is used by the processor, and the more energy adsorbed the more heat waste is generated. And for Max T-Junction, it’s the highest temperature the CPU can reach before starting to reduce its power and thermal throttle to cool down and stay within the normal operating range. Reaching a high thermal point can potentially cause thermal throttling which is performance loss as the processor tries to mitigate overheating by reducing processing frequency. These are great references for designing and planning the system’s cooling architecture.

What happens when a computer gets too cold or too hot?

For standard desktop PCs, the ideal operating range is usually around 10℃ to 27℃ and the warning level temperature range is around 1.7℃ to 32.2℃. Exceeding this warning range, commercial desktop PCs are prone to failure. When it’s too cold approaching the freezing point, the physical properties of the computer might flex and there is a risk of short circuit due to water condensation and can result in greater damage when compared to overheating. Also, when a system passes the warning heat range, internal components start thermal throttling, and the system can become too hot, dramatically reducing product lifetime and causing downtime during deployments.

In contrast, industrial computers are capable of withstanding a wide range of extreme temperatures ranging from freezing cold temperatures as low as -40℃ for super cold deployments like in the Arctic Ocean, up to incredibly hot 85℃ for scorching hot deployments during humid and hot summer environments like in remote oil production fields. Having a wide operating temperature range with extreme range makes industrial-grade PCs an ideal solution for rugged edge computing. Next, we are going to discuss the design and testing validation behind remarkable rugged industrial PCs.

Blueprint Behind a Durable Industrial PC

How Do Industrial PC Stay Cool? (Fanless Design & Passive Cooling)

Industrial embedded computers implement a fanless design as their cooling solution. Implementing a fanless design or passive cooling method provides various benefits compared to utilizing a fan for cooling. Fanless simply means the computer can dissipate the heat generated by the internal processors and other components without the use of a fan to cool down the system. That said, you first need to understand why circumventing a fan is crucial for a reliable, durable, and long-lasting system.

Using a fan to cool down internal components can be a straightforward solution for solving the computer needs for cooling. However, several major drawbacks are brought by using a fan for a computer cooling solution. One of the key design concepts of rugged industrial computers is to eliminate moving parts as much as possible. Applying a fan equals adding a point of failure and increasing the risk of computer downtime. With a Fan, it’s harder for industrial PCs to rank a high IP rating due to the need for venting holes to blow out the hot air off the system but at the same time exposing the internal parts from foreign particles and water droplets. Also, without a fan, there are no struggles to repair the fans and look for the right replacement. This allows the whole system to increases MTBF (mean time between failure), reduces downtime risk, and increases the device's life-cycle. Moreover, avoiding fans will result in lower power consumption, cleaner overall design, and a no-noise system during IoT deployments.

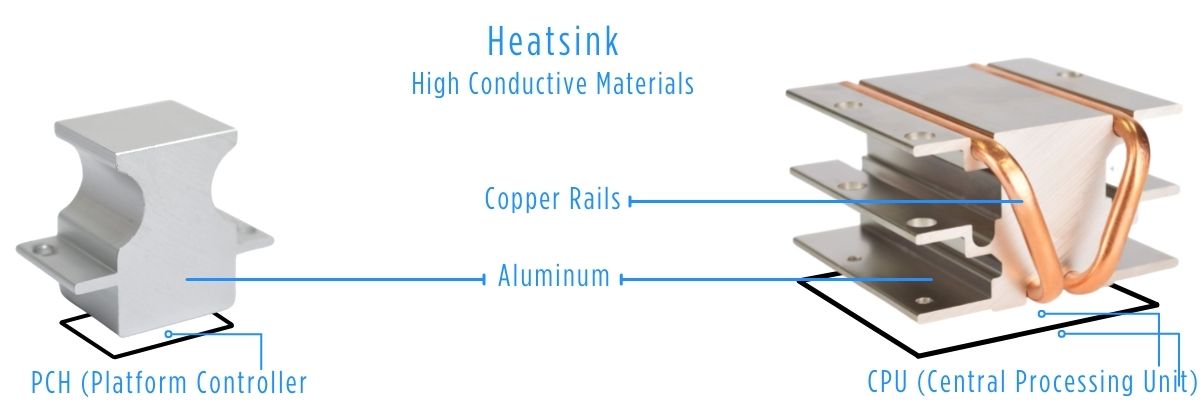

Industrial computers use heatsinks to passively cool down the internal components of the system and then dissipate the heat to the air around it. Heatsinks are made out of high thermal conductivity materials which are copper and aluminum. These ultra-conductive heatsinks are directly placed on computer components that generate most heat such as CPU and PCH (platform controller hub), attached heatsinks are capable of quickly dissipating heat away. Next, heatsinks will conduct heat to the one-piece chassis for dissipating the heat away.

The one-piece design chassis is designed as a multifunction case, working as a robust enclosure to protect the internal system from extreme shocks and vibrations while effectively dissipate heat away to cool down the system. That said, this allows the CPU TDP to operate up to 65 Watts without using any fan in an extended temperature range.

Test and Validation of Industrial Embedded Systems

To ensure that embedded industrial computers are completely reliable, durable, and long-lasting, rugged and industrial PCs are tested and validated in reliable testing facilities. To ensure the design of the system can smoothly operate within the harshest conditions, advanced testing facilities are specifically constructed to simulate real situations within extreme industrial environments where devices are being deployed. Then, the devices’ performances are measured and tested to the limit to ensure that they are capable of surviving harsh environmental conditions such as extreme temperatures. When testing and validating extreme temperature resistance, rugged industrial computers are going through three steps to guarantee their wide extreme temperature range capability. These tests are validated using IR Thermal Sensors, Temperature & Humidity Chambers and, Thermal Shock Ramp Chambers.

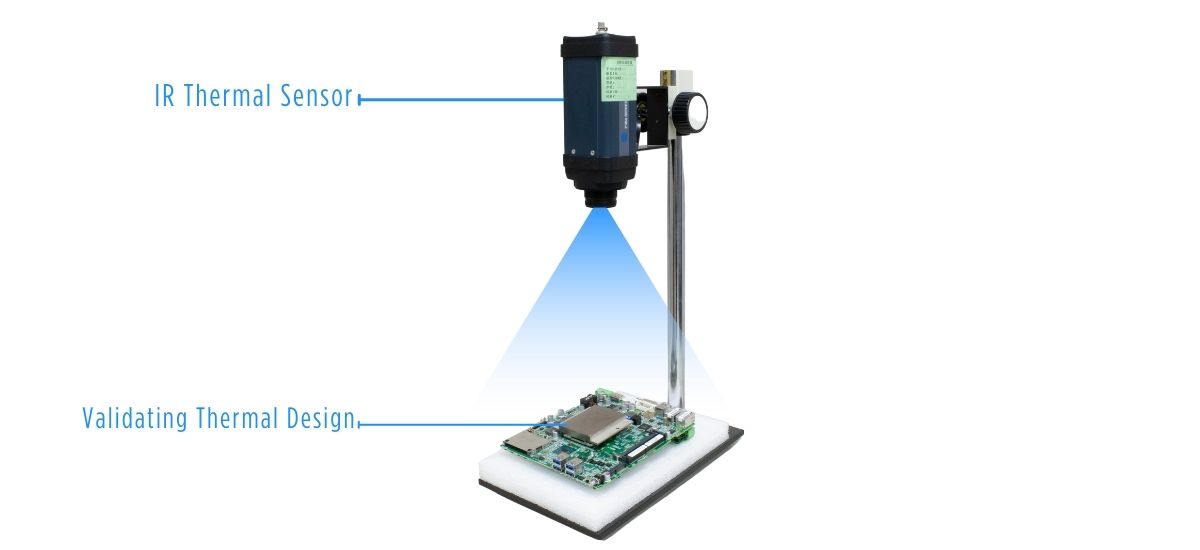

IR Thermal Sensors

In this first step, the goal is to validate the motherboard’s thermal designs to ensure that they are working efficiently and effectively in dissipating heat at the designated location. IR thermal sensors or Infrared thermal sensors are designed to detect devices infrared energy to accurately measure temperature generated by an object that can be detected from a certain distance.

In this picture, the computer is running a certain program to show how the heat flow and thermal design distribution function when the computer is running a program. With the IR thermal sensor, overheating semi-conductors or certain areas on the motherboard can be detected and accurately measured by the sensor. This data is then analyzed and processed to provide feedback on how well the thermal design is or what changes should be applied.

Temperature and Humidity Chamber

After the computer motherboard designs are validated from the IR Thermal Sensor, industrial rugged computers are tested in temperature and humidity chambers. This chamber basically works like a big oven that is capable of simulating real-life extreme temperatures and relative humidity situations while monitoring the computer performances to gather valuable data for validating the computer’s durability and reliability when getting deployed in extreme temperature environments.

These test methods comply with the IEC 60068 standard that is recognized internationally and developed by the International Electrotechnical Commission. The IEC test can help to validate electronic product’s ability to survive under various applied conditions such as storage, transportation, factory plant, operational environments, cities, and many more under extreme cold and heat situations. Rugged industrial PCs are also validated with PassMark BurnIn test software, which is special software that measures the overall functionality of the computer after specific run-time. This industry-standard test software provides an accurate representation of the computer’s reliability, stability, and endurance in harsh deployments.

Thermal Shock Ramp Chambers

Additionally, rugged industrial computers are also tested and evaluated for their ability to withstand sudden temperature drops in their surrounding environment. Thermal shock or temperature shock testing is just another test procedure to ensure greater reliability in the overall hardware designs for structural, mechanical, and electronic components used in embedded computers for harsh environments. Embedded computers are tested inside thermal shock ramp chambers to perform air-to-air thermal shock testing. Commonly, the test is tailored to provide a quick thermal shock using multiple chambers. Using two chambers with hot temperature and cold temperature can be effective in giving the thermal shock by moving devices in different compartments from hot to cold temperatures. Another way is to use a more advanced and programmable thermal chamber that can single-handedly perform rapid temperature changes without the need for moving the tested object.