Underground Mining: Digging Deeper with Powerful All-in-one Panel PCs

Today’s mining command center requires rugged solutions that can stand up to the elements, keeping miners safe, and deliver reliable, connected performance across the subterranean job site.

The Challenge

- Maximize efficiency and uptime in underground mining operations

- Create a “command center” from which miners can operate equipment remotely

- Combat harsh environmental pitfalls

- Eliminate reliance on consumer all-in-one panel PC options not built for rugged deployment

- Design for safety and efficiency

- Ensure design protects system longevity

- Deliver intuitiveness and performance

The Solution

- C&T’s rugged panel PCs engineered and certified to critical industrial standards

- Keeps mining operators safe and on task

- Machine control via immersive, albeit remote, experience

- Simulated, videogame-like experience allows equipment handling from safe distance

- Multifaceted visual data drives expert navigation of heavy machinery

- Excellent contaminant protection safeguards error-free performance

- High IP rating customized to deliver IP66 protection

- Corrosion-resistant stainless steel enclosure

- Durable glass surface with 7H hardness rating; resistant to scratches and breakage

- Clear visibility in poorly lit environments

- Ultra-sensitive projected capacitive touch (PCAP) to accommodate thick gloves

- Features 10 touchpoints, similar to common mobile phone technology

The Benefit

- Industrial panel PC serves as the brain of the underground mining command center

- Remote operation keeps personnel safe and in charge

- Scratch-resistant display purpose-built for mining environments

- Intuitive interface increases efficiency and eases strain on operators

- Hypersensitive projected capacitive touch validated for 13 different types of heavy work gloves, accommodating a large team of operators and mining specialists

- Wide-range power supply accommodates 9 to 50V sources

- Unstable power sources mitigated

- Wide operating temperature accommodates -10 to 60°C settings

- Configurable Wi-Fi support via antennae including 4G/LTE for reliable cellular reception

- Dependable connection for remote operating system (ROS) applications

- Warranty and support services increase longevity

The Company

Deploying sophisticated and efficient machinery, along with digitization, today’s mining modernization efforts have bolstered productivity while cutting costs. This subterranean approach has gained traction for its hardy yet precise ability to extract materials from below the earth’s surface – safely, economically and with minimal waste. In recent years, panel PC technology has broadened the appeal of underground mining, tapping into purpose-built rugged systems to improve efficiency, reliability and safety in rigorous underground as well as open pit environments.

This pivot has led one leading global supplier of mining and construction equipment to expand its product portfolio in recent years, embracing a mining ecosystem mindset. In listening and partnering with customers, this organization has collected valuable input to identify features and functionality that better equip personnel for the treacherous and taxing job at hand.

The Challenge

Today’s mining ecosystem relies on an intricate network of technology designed to maximize efficiency. From haul trucks and large drills to CPU power and wireless connectivity, if even one element falters, the entire worksite can grind to a halt. In this industry, there is absolutely no time for downtime.

To strengthen its already comprehensive slate of mining solutions, this construction equipment giant decided to integrate an all-in-one (AIO) computer into its advanced command center. It was critical that this PC support operations in harsh environments where dust, water, gas, humidity and uncontrollable ambient temperatures wreak havoc. Unfortunately, readily available consumer-grade computer products did not fit the bill. After testing a variety of COTS AIO computers, it was evident that a much more robust solution was necessary to sustain operations within such demanding environments.

Personnel in the underground mining command center need a system that not only enables the safe remote guidance of heavy vehicle and excavation equipment, but also allows for rugged, reliable operation in less than optimal conditions. For example, a thick-gloved hand manipulating equipment via an industrial-grade touch screen requires an ultra-sensitive, yet rock-hard surface that is not easily scratched by worksite elements like dirt and gravel. And, with real and significant risk of screen damage, monitor breakage has the potential to expose system operators to broken glass and debris.

The firm needed a rugged, waterproof touchscreen computer that could be integrated into its remote operating system and used to control a broad range of sensor-based systems above and below ground, both manually and autonomously.

The Solution

C&T’s WIO line of industrial touchscreen computers proved an excellent starting point for customized solutions for remote mining control. These rugged panel PCs are engineered and certified to critical industrial standards, offering a ready advantage in an asset aligned with the firm’s established BOM and required specifications.

C&T’s rugged panel PC keeps mining operators out of harm’s way and focused on machine control via an immersive, yet remote, experience. Much like a simulated training environment or an augmented/virtual reality video game, visual data surrounds the operator and allows the individual to control varied pieces of sophisticated equipment from a safe distance. This is driven by sensor data received in real-time from haulers, drillers, bolters, or other unique mining equipment that may be deployed at a particular jobsite. The resulting command center environment allows expert navigation of heavy machinery, tapping into visual data collected by sensors onboard the various pieces of equipment.

This industry leader was concerned about the aggressive water, dust, and debris exposure inherent to the uniquely harsh environment of underground mining. Previous consumer-grade technology implementation attempts had failed, confirming the need for exceptional protection against contaminants as a means to ensuring fault-free performance. C&T’s WIO series, a family of waterproof industrial panel PCs, had already demonstrated a high IP (Ingress Protection) rating and was customized to deliver IP66 protection for this rigorous mining application. With an IP66 design, the system’s corrosion-resistant Type 304 stainless steel enclosure is rated to prevent harmful ingress of dust and contaminants, including high-pressure water jets.

To combat the screen damage hazard, C&T’s design incorporates glass with a surface hardness rating of 7H, more durable and resistant to scratches and breakage. In addition, the panel PC’s high contrast ratio of 5000:1 helps operators act on the visual data supplied by the system. In colors displayed, whites are 5,000 times brighter than blacks, ensuring clear visibility in lighting-challenged environments.

C&T’s waterproof panel PC also features capacitive technology, a nonpressure,

touch-sensitive operation that functions by measuring change in capacitance, or the electrical field around the screen. Projected capacitive (PCAP) touch technology is particularly valuable in this application, enabling sensitivity to accommodate gloved or bare hands. In tuning the system’s PCAP levels for use in the harsh mining setting, C&T validated performance with 13 different types of protective industrial gloves to effectively handle the broadest range of operator preferences and safety requirements.

C&T’s PCAP design is optimized for the mining setting; its glass screen projects tiny electrical fields that enable touch recognition on the display surface as well as slightly above the surface. Human touch conducts small amounts of electricity, distorting the electrostatic field around the screen when touching or approaching it. Even in thick work gloves, this system requires little or no physical touch, providing the operator with a safe, comfortable and responsive control mechanism.

C&T’s PCAP technology also advances the overall ruggedness of the system itself. Because the screen can be covered by a top sheet of glass and completely enclosed, the system is even more fully protected against dirt, moisture and other contaminants. The screen and its protective layers are smooth and shatter resistant, a valuable asset to operators working in demanding, non-stop conditions. C&T’s WIO waterproof touchscreen computer features 10 touchpoints, creating a multi-touch control environment that performs as a familiar user interface with a modern approach – users can operate equipment with gestures such as touching or pointing with one finger, or pinch to zoom, rotate, or move objects as they as displayed.

The Benefit

C&T delivered a durable industrial panel PC solution that now serves as the brain of this global firm’s underground mining command centers. Mining staff are safely empowered to gain new efficiencies in remotely carrying out underground operations – removing operators from hazardous areas through automation.

WIO’s industrial-grade touchscreen gives the system improved scratch resistance, promotes a more natural interface engagement, and facilitates hypersensitive projected capacitive touch. Optional optical bonding can be incorporated to preserve visibility and vibrancy in humid areas.

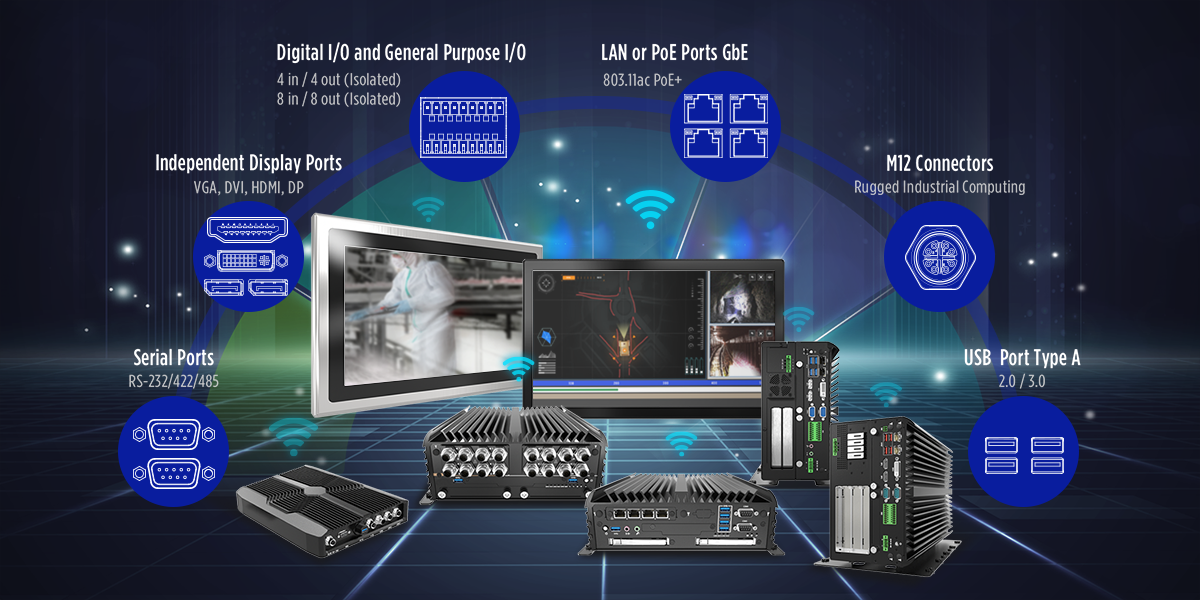

All WIO components are industrial grade, providing long life in terms of warranty and support services. Systems include high-performance 7th Gen Intel® Core™ i5 processors, tapping into greater longevity via the Intel® embedded roadmap. The system’s industrial-grade I/O and hardware controls are customizable and provide waterproof, corrosion-resistant M12 locking connectors as well as convenient Power On/Off, Auto, Menu, Up and Down commands in multiple languages.

The panel PC’s wireless options bring connectivity to any jobsite with configurable Wi-Fi support via antennae, 4G/LTE for reliable cellular reception and reliable connection for remote operating system (ROS) applications. Engineered for dynamic conditions, the C&T solution also offers a wide-range power supply to accommodate 9 to 50V sources. Over-voltage, over-current and reverse polarity protections mitigate unstable power sources. Operating temperature settings can range from -10 to 60°C.

Through a collaborative partnership, C&T has helped this mining equipment company integrate a solution that offers greater control, processing power, hardware longevity, and ongoing support to meet the needs of its customers and advance the mining industry’s shift from open pit to underground operations.