What is EN 45545 & EN 45545-2?

As automation transforms modern transportation, safety standards are becoming more stringent to ensure the reliability and protection of critical systems. In the railway industry, every material and component used in rail vehicles must comply with strict certifications such as EN 50155 and EN 45545. These standards are important because they guarantee the safety, reliability, and long-term performance of high-speed trains, regional railways, and industrial transportation systems.

While EN 50155 focuses on the environmental and electrical requirements for electronic equipment in railway applications, EN45545 sets the standard for fire safety protection in rail vehicles. In this blog, we'll explore the EN45545 certification and how it contributes to safer and more reliable railway systems.

What is EN 45545?

EN 45545 is the European fire safety standard specifically developed for railway vehicles to ensure passenger and crew safety in the event of a fire. It sets strict requirements for materials, components, and systems used in rail vehicles to minimize fire risks, limit the spread of flames, and reduce the generation of smoke and toxic gases.

The standard was first published in 2013 by the European Committee for Standardization (CEN) and is now widely adopted across Europe and other regions for rail vehicle compliance. It replaced various national fire safety standards, creating a unified framework for fire protection in rail applications.

Learn more

Who does EN 45545 apply to?

- Manufacturers of rail vehicles, including high-speed trains, regional trains, metro systems, and industrial transportation systems.

- Suppliers of components and materials used in rail vehicle interiors, exteriors, and technical systems.

- Operators and organizations responsible for ensuring rail vehicle compliance with fire safety standards.

What is EN 45545-2?

Building on the general framework outlined in EN 45545-1, EN 45545-2 specifically addresses the fire behavior requirements for materials and components used in railway vehicles. This part of the standard is critical for ensuring that materials contribute minimally to fire risks, limiting flame spread, smoke generation, and the release of toxic gases in the event of a fire.

Requirement Sets in EN 45545-2

EN 45545-2 introduces requirement sets that categorize materials and components based on their location and function in the rail vehicle. These requirement sets define the specific fire safety tests and performance criteria that the materials must meet. Some of the most relevant requirement sets for industrial computers and electrical equipment in railway applications include:

- R21: Electrical equipment in technical areas, such as control panels and industrial computers housed in cabinets.

- R22: Electrical equipment in internal applications, such as passenger compartments and driver cabins (e.g., on-board computers, passenger information systems).

- R23: Electrical equipment in external applications, such as roof-mounted or undercarriage systems.

- R26: Electrical equipment in passenger areas (e.g., passenger displays or driver consoles).

Each requirement set defines specific tests for flammability, smoke density, and toxicity, ensuring the highest level of safety for materials based on their deployment.

Hazard Levels in EN 45545-2

The Hazard Levels (HL) in EN 45545-2 define the stringency of fire safety requirements based on the risk profile of the rail vehicle. There are three hazard levels:

- HL1: Low risk (e.g., regional or suburban trains operating in open-air environments).

- HL2: Medium risk (e.g., intercity trains with limited tunnel exposure).

- HL3: High risk (e.g., high-speed trains, metro systems, or vehicles operating extensively in tunnels).

Materials and components must be tested to meet the hazard level relevant to the vehicle’s operational category and deployment environment. A material certified for HL3 automatically complies with HL2 and HL1, making it suitable for the most demanding applications.

| Design Categories | |||||

|---|---|---|---|---|---|

| Standard Vehicles (N) | Automatic Vehicles without trained staff (A) | Double-decked Vehicles (D) | Sleeping Cars and Couchette (S) | ||

| Operation Categories | OC-1 Open-air operations with easy side evacuation |

HL1 | HL1 | HL1 | HL1 |

| OC-2 Open-air and short tunnels where side evacuation is possible |

HL2 | HL2 | HL2 | HL2 | |

| OC-3 Long tunnels or enclosed stations, with side evacuation still feasible |

HL2 | HL2 | HL2 | HL3 | |

| OC-4 Underground or long tunnels with no easy evacuation routes |

HL3 | HL3 | HL3 | HL3 | |

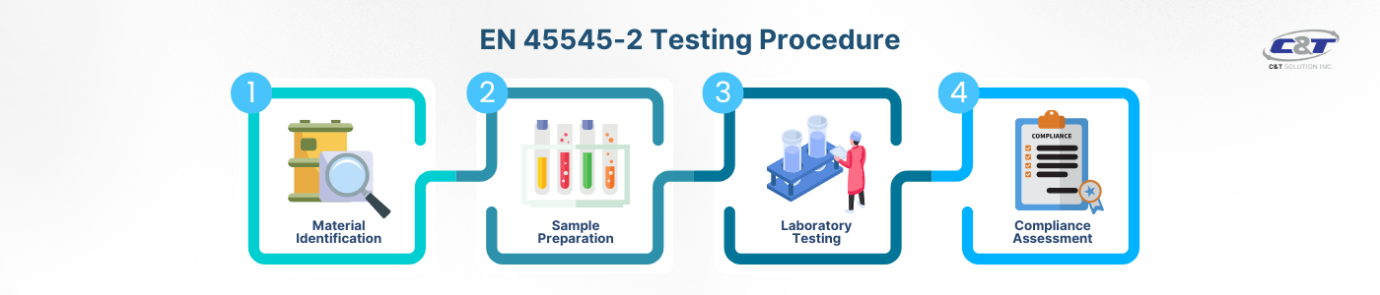

Testing Process for Industrial Computers

Industrial computers themselves are not directly tested for flammability, smoke density, and toxicity. Instead, the focus is on assessing the materials and components used in their construction. The testing process involves the following steps:

- Material Identification

The manufacturer identifies all the materials used in the industrial computer such as housing, cables, PCB laminates, connectors.

- Sample Preparation

Samples of the materials are extracted and prepared according to test standards.

- Laboratory Testing

Certifies labs conduct the tests under controlled conditions to measure flammability, smoke density, and toxicity.

- Compliance Assesment

The test results are compared against the thresholds specified in the EN 45545-2 for the applicable requirement set (Rxx) and hazard level (HL1, HL2, HL3).

Why EN 45545 Certification is Crucial for Industrial PCs in Railway Applications

For industrial PC manufacturers, EN 45545-2 compliance is essential for railway applications. The installation location—whether in passenger areas, technical compartments, or external mounts—determines the required requirement set and hazard level. Certification guarantees the product is safe, reliable, and meets the fire safety standards demanded by rail operators.

Adhering to EN 45545-2 enhances rail system safety and enables manufacturers to meet global regulatory requirements.

Explore our products or Contact us to consult with our rugged tech experts.

FAQ

- What is EN 45545 certification?

EN 45545 is the European fire safety standard for railway vehicles, ensuring materials and components meet fire protection requirements for passenger and crew safety.

- Why is EN 45545 important for industrial PCs?

EN 45545 ensures industrial PCs used in railways meet fire safety standards, reducing fire risks and ensuring compliance with regulatory requirements.

- What does EN 45545-2 cover?

EN 45545-2 focuses on the fire behavior of materials and components, setting requirements for flammability, smoke density, and toxicity.

- What are EN 45545-2 requirement sets?

EN 45545-2 defines three hazard levels: HL1 (low risk), HL2 (medium risk), and HL3 (high risk), with HL3 being the most stringent.

- What are EN 45545-2 requirement sets?

Requirement sets, like R21, R22, and R26, categorize materials and components based on their location and function in the railway vehicle.

- What is the difference between R22 and R23 in EN 45545?

R22 applies to internal electrical equipment, while R23 focuses on external applications like roof-mounted or undercarriage systems.

- Can an industrial PC certified for HL3 be used for HL1 applications?

Yes, a product certified for HL3 automatically meets the requirements for HL1 and HL2 since HL3 is the most stringent.

- Does EN 45545 replace national fire safety standards?

Yes, EN 45545 replaced multiple national standards to create a unified framework for railway fire safety across Europe.

- How does EN 45545 affect railway manufacturers?

Railway manufacturers must ensure all materials and components comply with EN 45545 to meet safety regulations and operational standards.

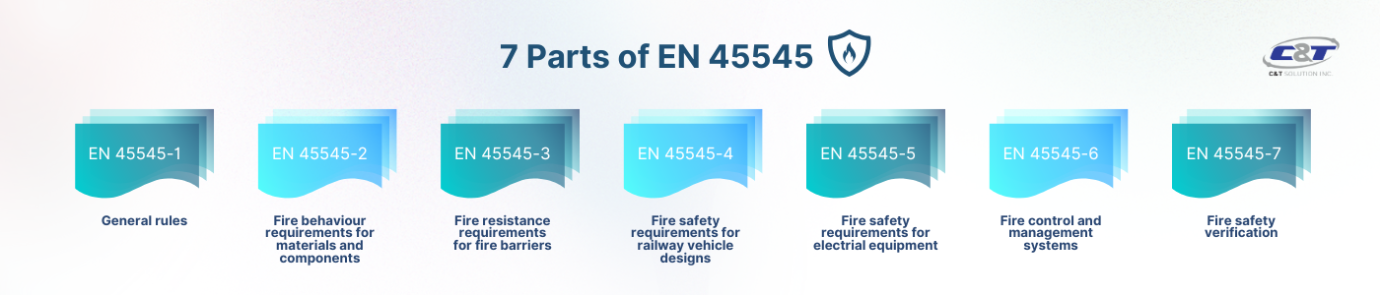

- How many parts does EN 45545 have?

EN 45545 is divided into seven parts, each addressing a specific aspect of fire safety in railway vehicles:

- EN 45545-1: General rules – Provides an overview of the scope and definitions of the standard.

- EN 45545-2: Fire behavior requirements for materials and components – Focuses on flammability, smoke, and toxicity testing.

- EN 45545-3: Fire resistance requirements for fire barriers – Details requirements for fire barriers in rail vehicles.

- EN 45545-4: Fire safety requirements for railway vehicles design – Specifies design measures to enhance fire safety.

- EN 45545-5: Fire safety requirements for electrical equipment – Outlines fire protection measures for electrical systems.

- EN 45545-6: Fire control and management systems – Covers fire detection, alarm, and suppression systems.

- EN 45545-7: Fire safety verification – Describes methods for verifying compliance with the standard.