Implementing Real-Time Analytics in Wastewater Treatment Using Industrial IoT Technology

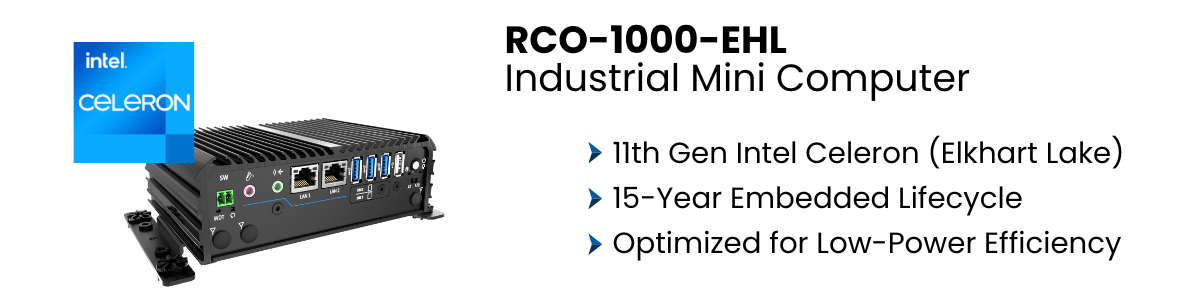

Wastewater treatment, crucial for water preservation and management, is advancing through digital transformation, particularly with the integration of IT/OT and IoT sensors. This case study explores how a leading company in wastewater management utilized C&T’s RCO-1000-EHL industrial mini computer to facilitate real-time data analytics.

Challenge:

- Needed a compact, real-time analytics-capable IoT gateway.

- Required suitability for NEMA enclosures with DIN-Rail mounting.

- Essential to withstand extreme temperatures and be UL Listed.

Solution:

- Utilized C&T’s rugged, fanless RCO-1000-EHL Series with IoT connectivity and necessary certifications (CE, FCC, UL Listed).

Benefit:

- OEM flexibility for rapid DIN Rail mount design.

- Turnkey image loading for easy field deployment.

- C&T’s efficient supply chain reduced the standard lead time.

This approach has empowered real-time analytical capabilities in wastewater treatment operations, enhancing efficiency and operational oversight.

The Company

This environmental resource management group, with over 170 years in operation, offers leading solutions for environmental protection and resource renewal. It boasts the largest private water services operation globally, managing over 8,500 water and wastewater facilities. The company delivers water treatment solutions across various sectors, from municipal utilities to industrial wastewater management.

The Challenge

The prominent water treatment company needed to replace their existing IoT gateway after it failed to perform within the stated wide operating temperature range. They sought a reliable edge computing manufacturer that could offer an effective solution. The new IoT gateway needed to be compact enough to fit into a small NEMA enclosure with DIN-rail configuration for outdoor use. Additionally, it was crucial that the IoT gateway be UL Listed to confirm compliance with safety standards.

After reviewing multiple edge computing providers, C&T was chosen as the primary supplier due to its extensive portfolio of ruggedized computing products and its comprehensive OEM manufacturing services for large-scale deployment.

The Solution

C&T recommended its RCO-1000-EHL Series fanless mini PC for its ultra-compact size, UL-listed certification, and extensive I/O support. This industrial mini computer fits perfectly into the compact NEMA enclosure, providing necessary edge processing capabilities and wireless connectivity. Real-Time Predictive Analytics for Water Treatment Operations

The integration of the RCO-1000-EHL reduces dependence on cloud computing and minimizes the risk of single-point failures that could disrupt operations. Powered by Intel’s 11th generation embedded processor, known as Elkhart Lake, it supports continuous real-time data aggregation and storage. This enables water treatment operators to remotely monitor and manage wastewater, facilitating real-time decision-making and predictive analytics that enhance operational efficiency.

Intel's Elkhart Lake processor is part of a long-term embedded roadmap, offering 15 years of product support to ensure consistent performance and compatibility.

IoT-Centric Connectivity for Seamless Data Flow

The RCO-1000-EHL serves as an IoT gateway, managing data from various sources such as pumps, pressure gauges, and water meters. It supports multiple connectivity options including USB, RJ45 LAN, and legacy COM ports, and can be enhanced with EDGEBoost I/O modules for additional flexibility. This setup ensures a cohesive data flow and a robust shared data ecosystem.

Operators in water treatment plants leverage these capabilities to analyze data comprehensively in control rooms, supporting predictive maintenance and full operational transparency.

Fanless & Cableless Design for Enhanced Reliability

The RCO-1000-EHL is engineered to withstand rigorous conditions, ensuring reliable 24/7 operation in extreme outdoor temperatures within the NEMA enclosure, maintenance-free throughout its lifecycle. Its rugged design, which includes wide temperature tolerance, shock and vibration resistance, and a broad power input range, is fanless and cableless. These features have been rigorously tested and validated to meet UL Listed safety standards, ensuring a dependable setup for deployment.

The Benefits

C&T has become the go-to provider for the water treatment company’s industrial computing needs, thanks to its deep expertise and extensive range of rugged edge computers. Before partnering with C&T, the company struggled with OEM flexibility and long-term support.

With over 10 years of experience in rugged edge manufacturing, C&T was able to meet all deployment specifications seamlessly. The RCO-1000-EHL was custom-designed with a side DIN-rail mount for easy integration into the existing NEMA enclosures and ensured long-term depot support. C&T’s capabilities in system integration were also crucial in loading the necessary operating system and water asset management software, facilitating smooth field deployments. Additionally, C&T’s US-based OEM manufacturing services have allowed the water treatment company to optimize their deployment processes and focus more on core operations.

Thanks to C&T’s proactive sales, engineering, and supply chain teams, the company could bypass the usual 12-week lead time, opting instead for scheduled just-in-time inventory deliveries that enhanced their market responsiveness. Overall, the water treatment company greatly valued C&T’s adaptability and support throughout their project.